The Thin Films and Electrical Measurements Laboratory is designed for the production of thin films, as well as their integration into functional devices and electrical characterization. Its infrastructure features a clean room (100 m2) equipped with systems of thin film deposition with physical vapor (PVD) via e-beam, oxide deposition by ALD (atomic layer deposition), reactive ion etching (RIE) system, and photolithography processes. The lab also provides facilities for thin films deposition by dipcoating, spincoating, inkjet printing, and as a Molecular Beam Epitaxy (MBE) system for growing III-V monocrystalline compounds and heterostructures based on As, Ga, Al, In, and Si. The facilities designed for the electrical characterization of materials and devices feature a PPMS (Physical Parameter Measurement System) Dynacool (1.8 K – 400K) with dilution refrigerator (up to 50 mK) that can work with magnetic fields of up to 14T, cryogenic and cryogen-free probe stations, semiconductor parameter analyzers (Keithley 4200 SCS), potentiostats, oscilloscopes, lock-in amplifiers, among others.

Equipment

Equipment

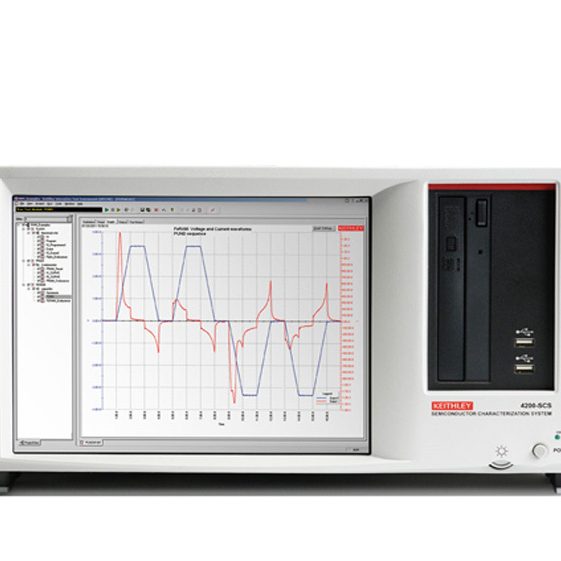

Analisador de Parâmetros Semicondutores Keithley 4200A

Multi-user equipment – Process FAPESP 2023/09395-0

Features

The Laboratory of Thin Films and Electrical Measurements, located at the Brazilian Nanotechnology Laboratory (LNNano/CNPEM), will be offering the external community the Keithley 4200A Semiconductor Parameter Analyzer, designed for the characterization of thin films and electrical measurements. This resource will be available to national and foreign researchers interested in exploring the nanometric properties of materials and devices.

Operation

The parameter analyzer is designed for the electrical characterization of materials, thin films, and semiconductor devices through current-voltage (I-V) and capacitance-voltage (C-V) measurements with a high degree of precision and resolution. The unit is based in the LNNano’s Thin Film and Electrical Measurements Laboratory, comprising a clean room and laboratories equipped for research and prototyping.

Useful information:

User access: submissions via SAU Online.

Submitting proposals: see the guide to submitting proposals.

Features and techniques: access Thin Films and Electrical Measurements Laboratory.

Contact: visit the Team page.

Electron beam deposition

Specifications:

- Source: 6 kV– 10 kV;

- Current: max. 190 mA;

- Sample size: ≤100mm;

- Heated sample holder: up to 500°C;

- Deposition chamber with capacity for up to 6 targets;

- Working pressure on the order of 1 x 10-7 Torr;

- Allowed materials: Cr, Au, Ti, Ni, Ag, NiFe, Ge, SiO, SiO2, among others upon request.”

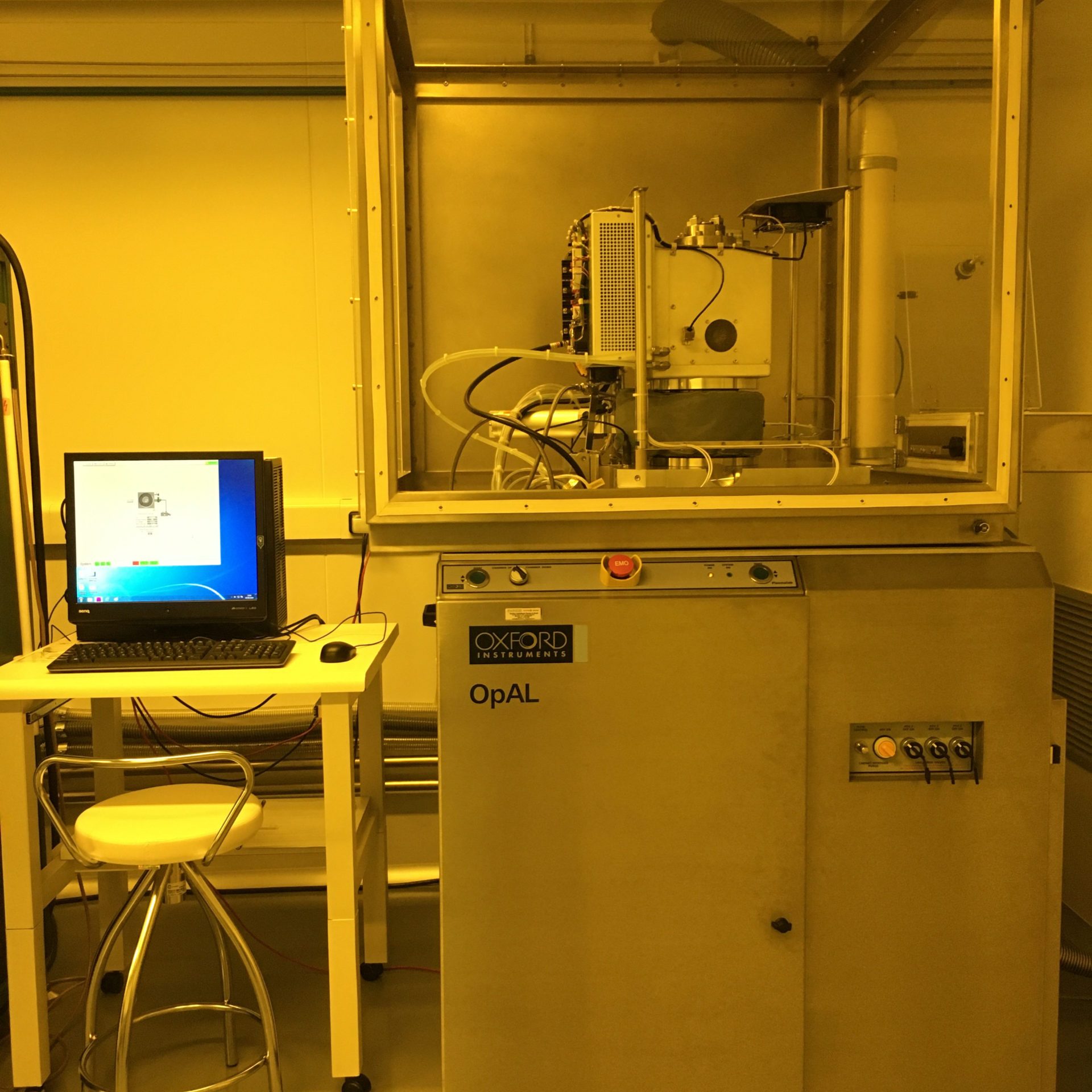

Atomic layer deposition

Specifications:

- Sample size: ≤ 100mm.

- Available processes:

- Al2O3 – Thermal deposition (TMA precursor);

- TiO2 – Plasma Deposition (TTIP Precursor); Deposition chamber with capacity for up to 6 targets;

- Working pressure on the order of 1 x 10-7 Torr;

- Allowed materials: Cr, Ti, Ni, Ag, NiFe, Ge, SiO, SiO2, among others upon request.”

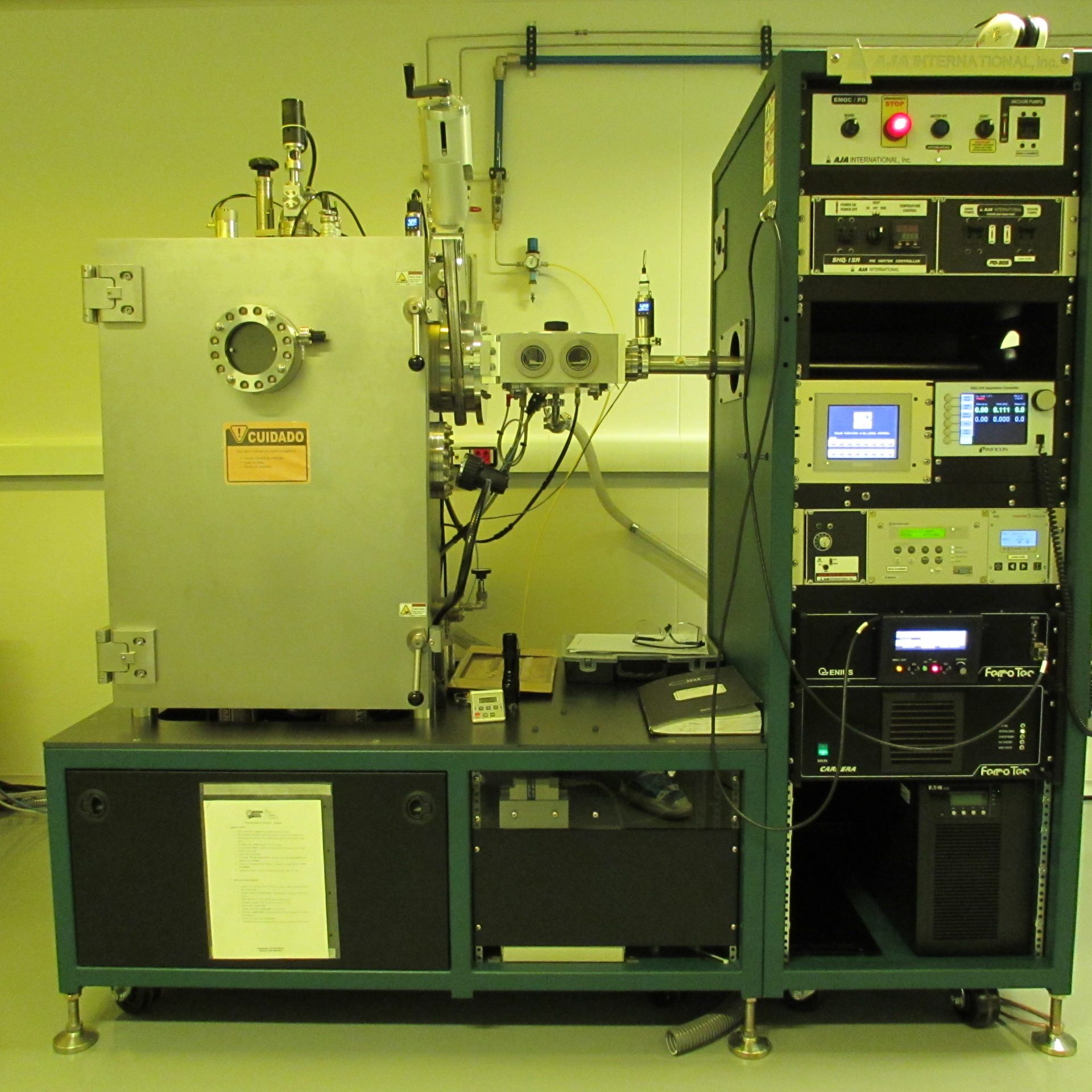

Sputtering deposition

Specifications:

- Source: DC

- Sample size: A few mm up to 6 x 177 mm wafers.

- High density plasma beam;

- Allows reactive sputtering: O2 and N2 gases;

- 4 manual rotating targets;

- Working pressure in the order of 8 x 10-7 mbar;

- Allowed materials: Cr, Au, Ti, Ni, NiFe, Al, Cu, Pt, Pd, Wti, among others upon request.

Electron beam deposition

Specifications:

- Source: 4 kV;

- Current: max. 190 mA;

- Sample size: ≤100mm;

- Deposition chamber with capacity for up to 2 materials; Working pressure in the order of 1 x 10-6 mbar;

- Allowed materials: Cr, Au, Ti, Al, Ni, Pt, Fe, SiO2 among others, on request.

Sputtering deposition

Specifications:

- Source: DC/RF

- Sample size: up to 76 mm.

- Sample holder heating: up to 600°C;

- Target-Substrate Distance: Variable;

- Fully computer controlled;

- Loading chamber separate from main;

- Independent deposition of up to 5 simultaneous materials;

- Allows reactive sputtering: O2 and N2 gases

- 6 confocally mounted targets

- Working pressure in the order of 2 x 10-8 Torr

- Allowed materials: Cr, Au, Ti, Ni, NiFe, Al, Cu, Pt, Pd, Wti, Fe, Si, Ge, SiO2, TiO2, among others upon request.

For Au depositions, user’s contribution is required.

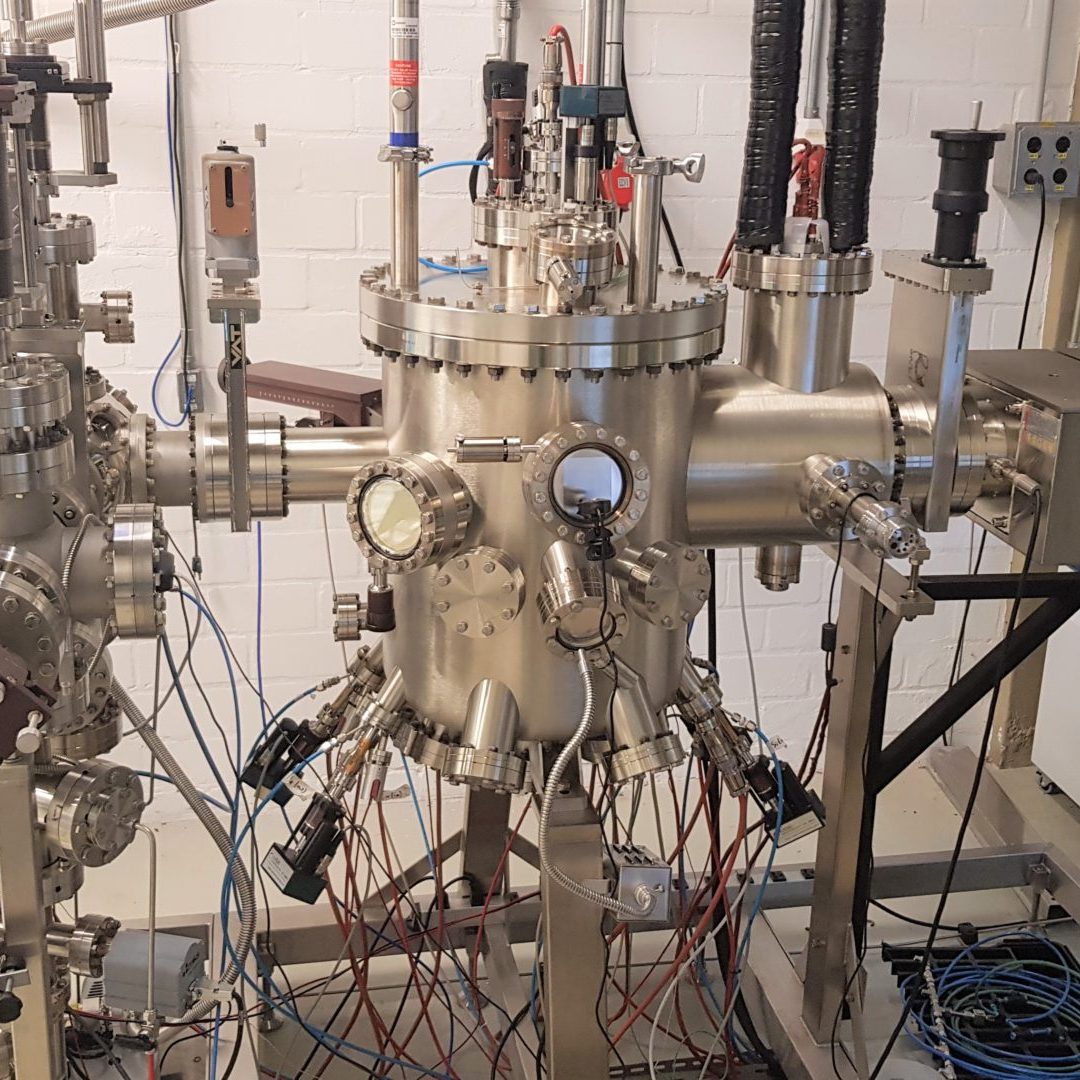

Epitaxial growth system – MBE III-V

Specifications:

- Bottom pressure: ~ 1 × 10-10 mbar;

- Sources: arsenic (As), gallium (Ga), silicon (Si), aluminum (Al), indium (In);

- 15 kV High Energy Reflected Electron Diffraction (RHEED) system integrated with iRHEED data acquisition system;

- Hydrogen beam for substrate surface cleaning;

- Substrate size: maximum 2” diameter”

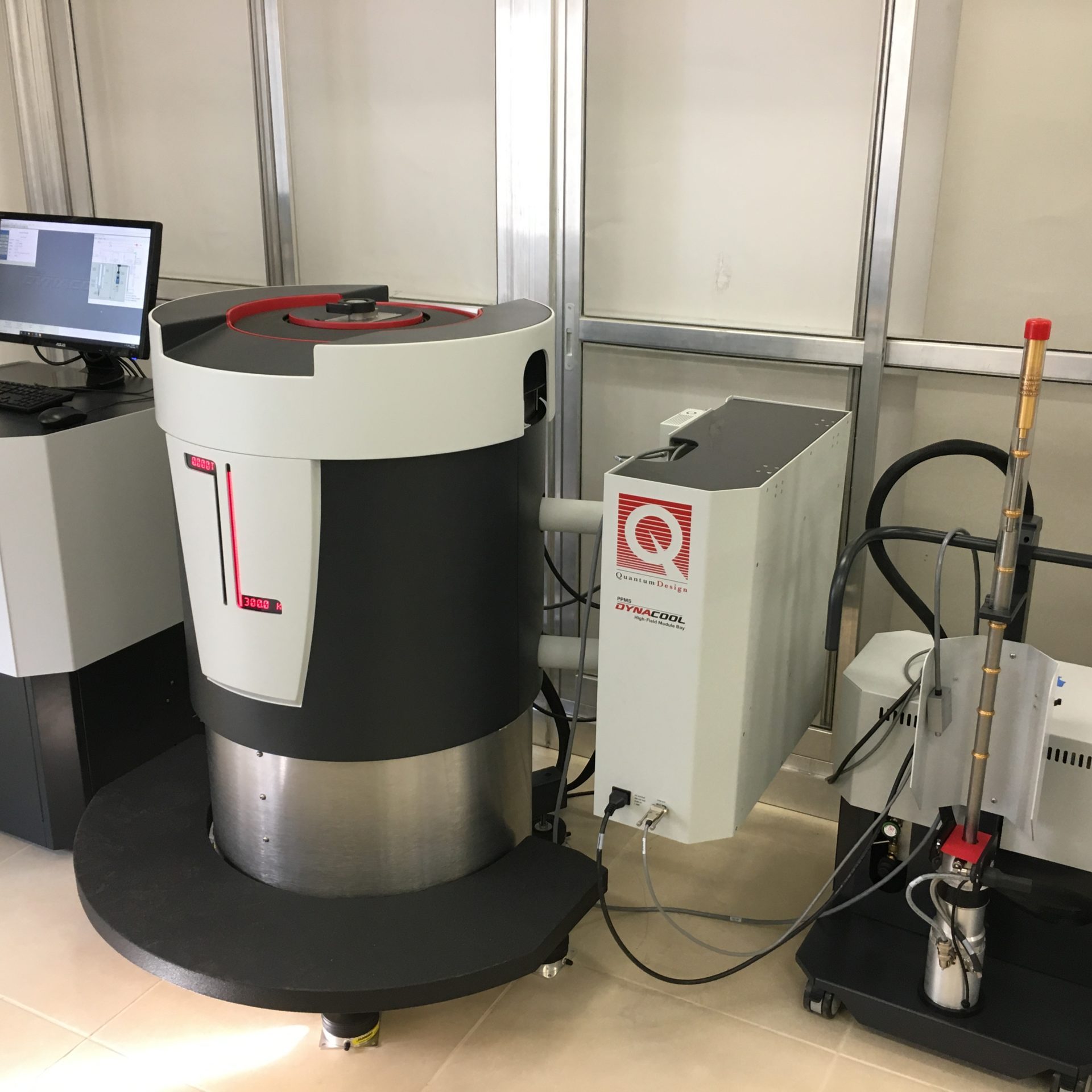

PPMS

Specifications:

- Temperature: 50 mK – 4 K (With dilution cooler *)

- 1.8 K – 400 K (Conventional Mode);

- Characterization types: ETO (electrical measurement), Specific Heat;

- Magnetic field: 0 to ± 14 T;

- Sample size: ≤ 8mm

- ≤ 3 mm (for specific heat).

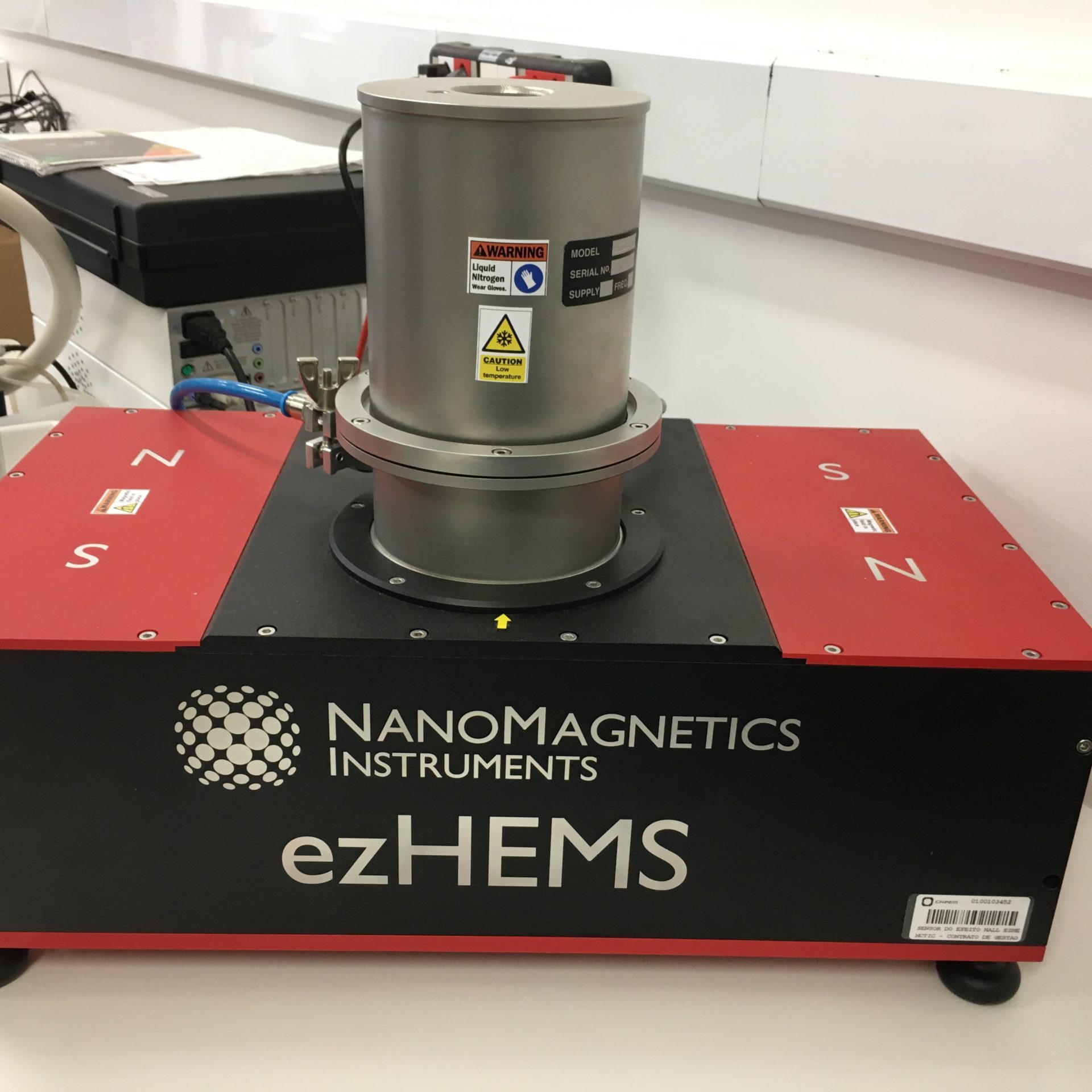

Hall effect measurement

Specifications:

- Sample size: ≤ 12mm x 3mm x 12mm (W x H x D);

- Up to 6 electrical contacts;

- Van der Paul measure;

- Measured by Hall Bar;

- Temperature: 80 K (with liquid nitrogen)

- 300K

Current x voltage measurement (IxV)

Specifications:

- Parameter Analyzer

- 4 SMUs – 2x 4210-SMU and 2x 4200-PA

- Current source: Max 1A, Min 1fA

- Voltage source: Max 210V, Min 5 µV

- Available module: 4210 – CVU

- Frequency: 1 kHz to 10 MHz (fixed frequency)

- AC output: 10 mV to 100 mV RMS

- DC output: +/-30 VDC

Potentiostat / Galvanostat

Specifications:

- Electrode connections: 2, 3 and 4;

- Voltammetric, amperometric, galvanostatic and impedance measurements;

- Potential range: +/- 10V;

- Compliance voltage: +/- 30V;

- Maximum current: +/- 2 A;

- Current ranges: 1 A to 10 nA (100 pA with ECD module);

- PC interface: USB;

- Control software: NOVA;

- Extra modules: FRA32M and ECD;

- FRA / EIS: 10 μHz to 1 MHz.

Optical microscope

Specifications:

- Sample Size: Up to 100mm;

- Available lenses (conventional optical microscope): 5x, 10x, 20x, 50x, 100x and 150x;

- Software for measurements and photographs;

- Manual operation;

- Available inside cleanrooms for inspection of samples in processing.

Polypropylene fume hoods for sample cleaning

Specifications:

- Sample Size: Up to 100mm;

- Available lenses (conventional optical microscope): 5x, 10x, 20x, 50x, 100x and 150x;

- Software for measurements and photographs;

- Manual operation;

- Available inside cleanrooms for inspection of samples in processing.

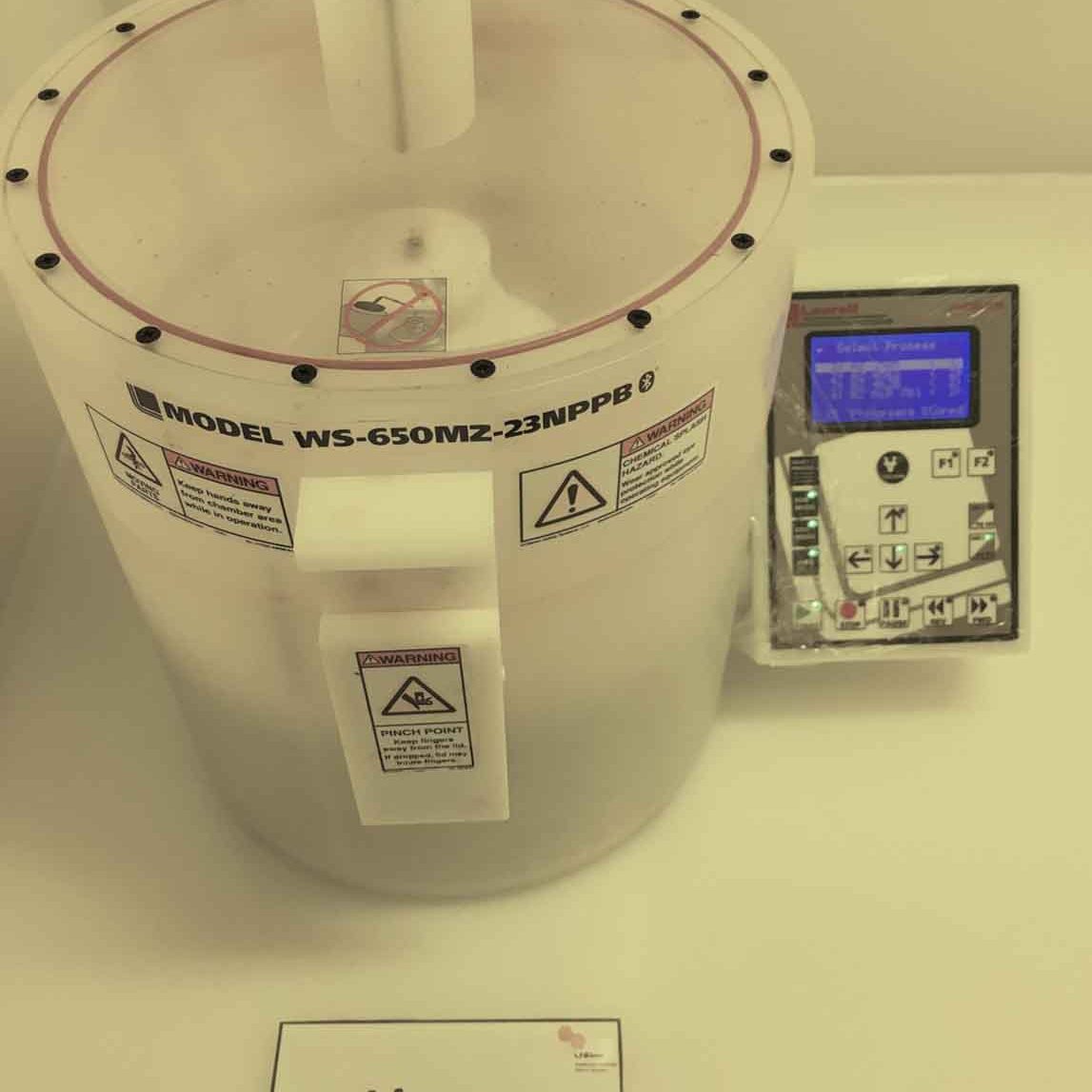

Sistema de deposição de filmes por spincoating

Especificações:

- Tamanho de substratos: Até wafers de 100 mm de diâmetro;

- Velocidade máxima: 8.000 rpm;

- Vácuo: Venturi (Amostras pesadas devem ser rotacionadas com velocidade menor – risco de serem arremessadas).

Thermo vacuum oven for heat treatment

Specifications:

- Temperature: up to 320°C

- Available gases: Ar, N2

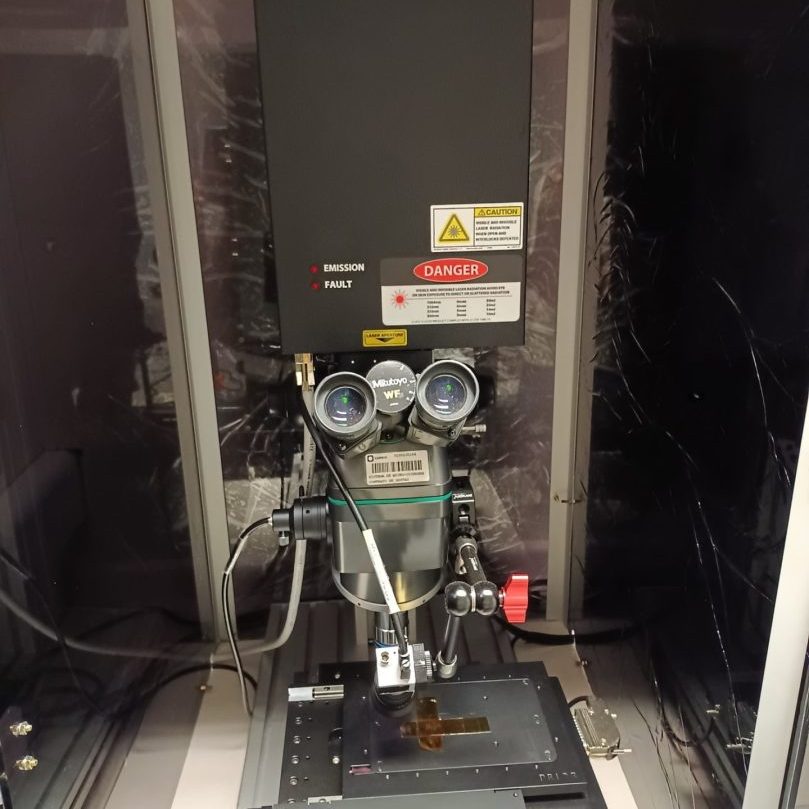

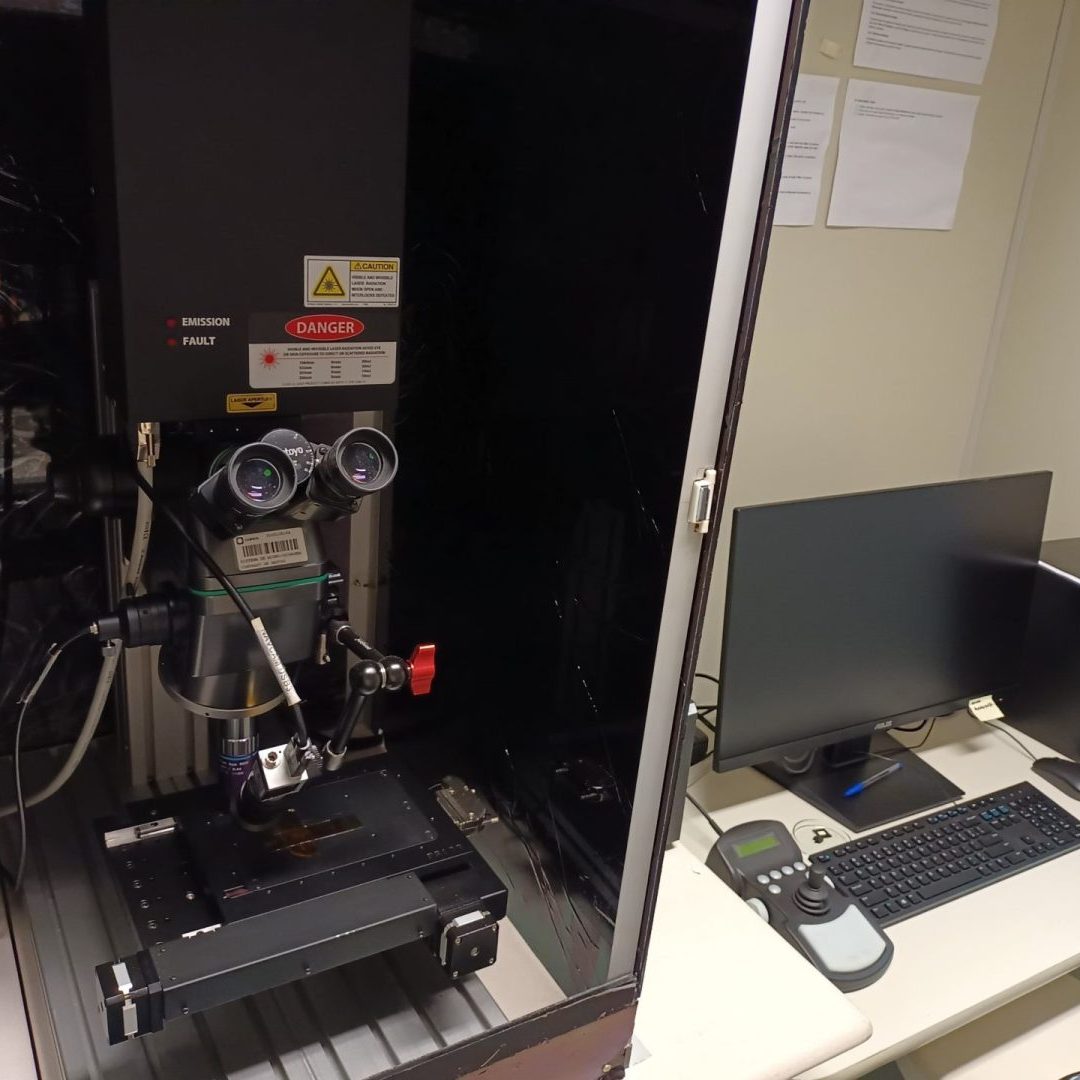

Laser Ablation System (Micro-Surface Machining)

Features:

- Nd:YAG pulsed laser, 6 ns pulses.

- Wavelengths/power:

- Green (Green High): λ = 532 nm @ 1.29 mJ.

- Green (Green Low): λ = 532 nm @ 0.31 mJ.

- Ultraviolet (UV High): λ = 355 nm @ 0.42 mJ.

- Ultraviolet (UV High): λ = 355 nm @ 0.11 mJ.

- Square aperture from 1 to 47.9 μm of spot.

- Frequencies up to 50 Hz (pulses/s).

- Sample size up to 100 x 100 x 30 mm (W, L, H).

- Removal of thin films from metals and oxides.

- Detailed structures can be created via .dxf files.

- Get to know the division

- Facilities

- In-situ Growth Laboratory (LCIS)

- Spectroscopy and Scattering Laboratory

- Photoelectrochemistry Laboratory

- Transmission Electron Microscopy Laboratory

- Scanning and Dual-Beam Electron Microscopy Laboratory

- Atomic Force Microscopy Laboratory

- Nanoceramics Processing Laboratory

- Nanomaterials Synthesis Laboratory

- Staff

- Contact us