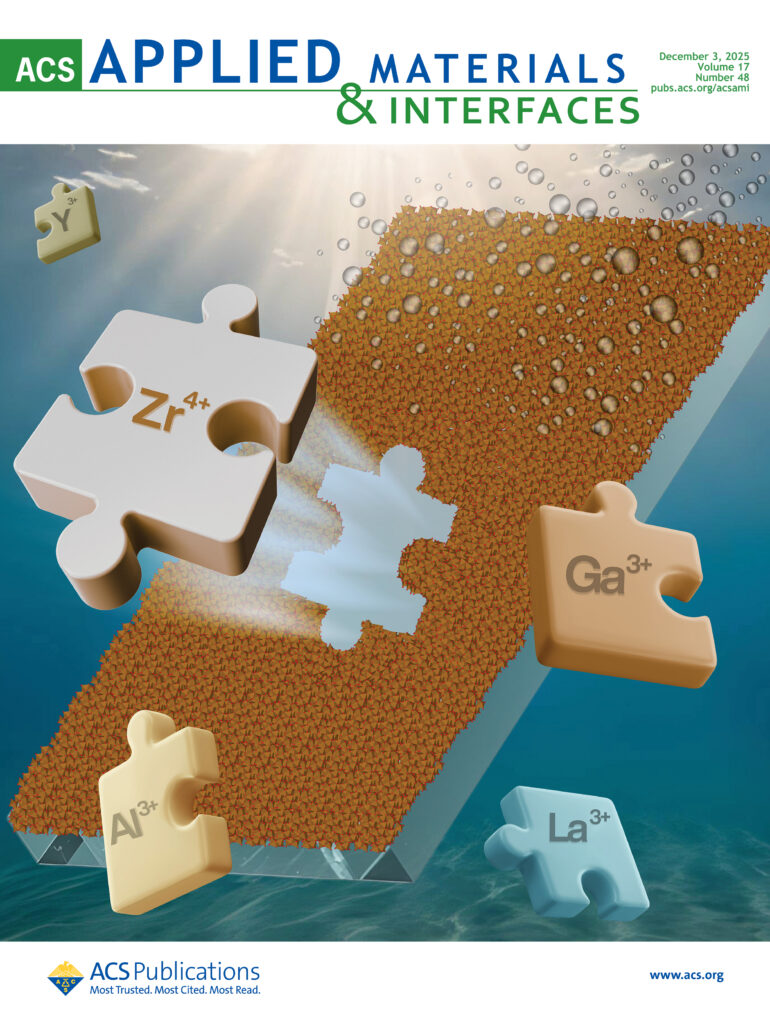

The study, featured on the cover of ACS Applied Materials & Interfaces, transforms the classic methodology into a highly selective and scalable route, capable of adjusting different properties of synthesized materials, such as optical, electronic, catalytic, and others, according to the desired application

Research conducted by scientists from the Brazilian Center for Research in Energy and Materials (CNPEM), a social organization linked to the Ministry of Science, Technology and Innovation (MCTI), was featured on the cover of the journal ACS Applied Materials & Interfaces. The study presents an unprecedented approach to manufacturing metal oxide-based materials with adjustable properties from the synthesis stage onwards, which represents a strategic advancement for the production of technologies such as green hydrogen, heterogeneous catalysis, sensors, and oxide-based electronic devices.

The team led by the researcher from CNPEM’s Brazilian Nanotechnology National Laboratory (LNNano/CNPEM), Flavio Leandro Souza, reformulated the traditional polymer precursor solution (PPS) process, widely used in the synthesis of metal oxides, transforming it into a more efficient, selective and scalable route. The developed approach allows for the incorporation of different chemical elements into a single solution, directing each dopant to specific locations within the nanostructure.

In this study, the researchers chose to produce iron oxide in the hematite phase as a proof of concept. The choice is due both to the abundance of this mineral in Brazil and to its potential application in areas ranging from medicine to energy.

Enhanced performance of hematite

The work focused on the use of hematite as one of the components of photoelectrochemical cells — devices that, when illuminated by sunlight and in contact with water, promote reactions that break the H₂O molecule, generating hydrogen (H₂) and oxygen (O₂).

“Hematite is a promising material, but its performance is still hampered by well-known structural and electronic limitations. The route we developed allows us to address these bottlenecks precisely, adjusting essential properties such as electron mobility, porosity, grain size, and film thickness. These factors have a direct impact on the photoelectrochemical performance of hematite”, says Souza.

The study also shows that two forms of doping, intrinsic and extrinsic, can be used in a complementary way in the same material. Intrinsic doping, for example, can modify the electronic structure within the grains, while extrinsic doping can reduce the energy of the electronic barriers at the interfaces, in addition to preventing excessive crystal growth and maintaining their nanometric scale.

“When applied together, these strategies allow for the simultaneous optimization of electronic transport at different scales, which is uncommon in metal oxides. This combination significantly enhances the performance and functionality of the materials produced”, explains Souza.

To validate the method, dopants considered challenging by the scientific literature for application as photoanodes in photoelectrochemical cells were selected, including aluminum and zirconium. The process developed at CNPEM allowed these elements to show a performance far superior to that usually obtained for pure hematite. As a result, it was possible to produce a hematite photoanode with up to eight times greater solar-chemical energy conversion efficiency.

Souza points out that the choice of these doping agents was strategic: the intention was to demonstrate the robustness of the new route using elements that historically showed limited performance. Even so, the results obtained exceeded by more than three times the best value ever reported in the literature for these same doping substances.

In addition to experiments conducted with hematite, the team also synthesized other materials, such as CuO and CeO₂, both in their pure form and modified with various dopants. These oxides, widely used in multiple technological applications, were employed to experimentally demonstrate the versatility and effectiveness of the proposed approach.

Scaling and technology transfer

In addition to conceptual advances, the method also demonstrated robustness, reproducibility, and stability when applied in a controlled manner and under real-world conditions on a large scale. In a previous study, published in the journal ACS Energy Letters, the same approach was used to produce over one hundred large-area hematite photoanode electrodes, all exhibiting reproducible performance when integrated into complete modular photoreactors operated with sunlight. The consistent performance of these devices highlighted the industrial potential of the route, which simplifies traditional steps and allows the manufacture of complex materials in less than 24 hours.

The new method resulted in a national and international patent, with protection extended to Europe and the United States. Beyond applications focused on renewable hydrogen production and catalysis, the methodology can also be used for the production of anti-corrosion coatings, optoelectronic devices, functional packaging, sensors, and energy storage components.

The work carried out is aligned with the goals of the Center for Molecular Engineering for Advanced Materials (CEMol), coordinated by CNPEM within the scope of the CEPID/FAPESP program. “The study represents a concrete example of the center’s purpose, which seeks to develop methodologies capable of creating on-demand materials with adjustable properties for scientific and industrial needs. Our article demonstrates the maturity of a route that offers a rational and efficient way to design functional materials”, says the researcher.

The research was conducted by a multidisciplinary team from the Brazilian Nanotechnology National Laboratory (LNNano/CNPEM), in collaboration with the State University of Campinas Institute of Chemistry (Unicamp), and the Center for Natural and Human Sciences of the Federal University of ABC (UFABC).

About LNNano

The Brazilian Nanotechnology National Laboratory (LNNano) works in research and development at the nano scale using sophisticated infrastructure and highly specialized teams that can search for answers to scientific challenges and leverage technology solutions. Its open facilities comprise a center that is unrivaled in Brazil and include electron and atomic force microscopy, as well as clean rooms and laboratory spaces that allow activities ranging from materials synthesis and characterization to device manufacturing. Scientific research at LNNano covers strategic topics where nanoscience and nanotechnology can help solve problems facing the country, in areas like renewable energy, materials for sustainability, health and quantum devices. LNNano is part of the Brazilian Center for Research in Energy and Materials (CNPEM) in Campinas, São Paulo, a private, non-profit organization overseen by the Ministry of Science, Technology and Innovation (MCTI).

About CNPEM

The Brazilian Center for Research in Energy and Materials (CNPEM) houses a cutting-edge, multi-user and multidisciplinary scientific environment, with actions in different areas of the National Science, Technology and Innovation System. A Social Organization supervised by the Ministry of Science, Technology and Innovation (MCTI), CNPEM is driven by research that impacts the areas of health, energy, renewable materials and sustainability. Responsible for Sirius, the largest scientific equipment ever built in the country, CNPEM currently develops the Orion project, a laboratory complex for advanced research on pathogens. Highly specialized science and engineering teams, sophisticated infrastructures open to the scientific community, strategic lines of investigation, innovative projects with the

productive sector and training of researchers and students constitute the pillars of this unique center in the country, capable of acting as a bridge between knowledge and innovation. The CNPEM is responsible for the operation of the Brazilian Synchrotron Light Laboratory (LNLS), the Brazilian Biosciences National Laboratory (LNBio), the Brazilian Nanotechnology National Laboratory (LNNano) and the Brazilian Biorenewables National Laboratory (LNBR), as well as for the Ilum School of Science, a bachelor’s degree course in Science and Technology, supported by the Ministry of Education (MEC). https://cnpem.br/